Manufacturers of:

Premium Products

|

Epoxy Mortar patches & resurfacers |

Rapid Set concrete mender and Patch |

|

A two component hybrid urethane packaged in 300ml x 300ml dual cartridge system. This product can be used for the repairing of spalled concrete, holes, cracks, threshold, or uneven concrete slabs where an area needs to be placed back in service within 30 minutes. |

|

Rigid-Rock RR 1230 Rapid Set Concrete Mender Patch |

|

Pourable Self-Leveling Resurfacer Patch |

|

Two-component resin plus fine aggregate system used as a pourable patch or for restoring mildly deteriorated surfaces and providing the foundation for a highly smooth finish. This is the ideal product for Clean Rooms, Research and Laboratories or any areas that a smooth, seamless and highly cleanable surface is needed. |

|

Rigid-Rock RR 1022 Self Leveling Epoxy Resurfacer |

|

Industrial & heavy Duty Epoxy Mortar Patch |

|

Resin-rich heavy-duty mortars, offering the highest combination of compressive and flexural strength, for heavy load, high impact and abrasive areas. The premier formulation for loading docks, machining areas and heavy traffic aisles using steel wheels and fork-lifts. |

|

Rigid-Rock RR 1005 Economic Industrial Epoxy Mortar Patch |

|

Rigid-Rock RR 1010 Heavy Duty Epoxy Mortar Patch |

|

|

Low Temperature & Quick Set Epoxy Mortar Patch |

Resin-rich mortar ideal for resurfacing and patching low temperature areas, such as cold storage, freezers and unheated areas where most epoxies cannot cure in a suitable time frame, if at all. At elevated or ambient temperatures They can also be used as a quick patch for repairs at ambient temperatures to minimize downtime. |

|

Rigid-Rock RR 1206 Low Temperature Quick Set Epoxy Mortar |

|

Rigid-Rock RR 1208 Sub-Zero Arctic Formulation Epoxy Mortar |

|

Food Processing Epoxy Mortar Patch |

|

Formulated especially for the demanding environments of the Food Process Industry, these formulations withstand the rigorous requirements of cold area wash down thermal cycling, sanitizing chemicals and high load traffic. All products meet USDA requirements and are available with Anti-Microbial properties. |

|

Rigid-Rock RR 1205 Low Temperature Quick Set Food Process Epoxy Mortar |

|

Rigid-Rock RR 1530 Food Process Grade Epoxy Mortar |

|

High Tempurature Urethane Mortar |

|

This is a three component urethane mortar that has outstanding wear performance. Product is available in smaller kits for patching over existing urethane mortar systems or other concrete exposed to harsh conditions. Urethane mortars have good thermal shock capabilities and are a good choice for hot wash down areas. Product Benefits: Thermal shock resistant, Great for patching over existing urethane mortar systems, and good freeze/thaw stability. Capable of withstanding harsh temperatures, acids, alkalis and other harsh chemicals, fatty greases, salts and solvents and U.S.D.A. accepted makes it ideal forfor the food industry. |

|

Rigid-Rock RR 1591 Waterbased Cement Urethane Mortar Patch Kit/Resurfacer |

|

Rigid-Rock RR 1592 SL Waterbased Cement Urethane Slurry Patch Kit/Resurfacer |

|

.jpg) |

Chemical Resistant Epoxy Mortar Patch |

Specially formulated from exceptional blends of polymers and Novolac resins to provide the maximum level of acid and chemical resistance available. Formulated to withstand harsh chemicals used in fruit and vegatable production, anodizing lines, pickling lines, plating lines, secondary containment areas and other aggressive chemical environments. |

|

Rigid-Rock RR 1420 Acid & Chemical Resistant Epoxy Mortar |

|

Rigid-Rock RR 1456 Extreme Chemical Resistant Novolac Epoxy Mortar |

|

|

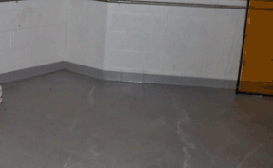

Cove & Vertical Epoxy Mortar Patch |

Designed from a combination of unique polymers and fine aggregates formulated for applications on vertical and overhead surfaces, to provide effortless installation of vertical areas with minimal slump. Providing a professional look when installing radius coving or mitered cants, they also have excellent chemical and thermal resistance making it ideal for food process and acid/chemical areas and are the most versatile for scratch coats, filling honey-combs or patch and repairs. |

|

Rigid-Rock RR 1701 Vertical Coving Formulation Epoxy Mortar Patch |

|

Rigid-Rock RR 1702 Vertical Overhead Formulation Epoxy Mortar Patch |

|

|

Specialty Epoxy Mortar Patch |

Specially designed formulas for asphalt, heavily oil contaminated areas or even underwater for sealing wood block, lot repairs and the most challenging applications in the harshest environments that exist in Foundry, Manufacturing, Food Process, Plating and Pulp and Paper Industries. |

|

Rigid-Rock RR 1301 Coal Tar Hybrid Epoxy Mortar Patch |

|

Rigid-Rock RR 1601 Low Temperature Underwater Epoxy Mortar Patch |

|

Applied Polymer Solutions, LLC

507 Five Leaf Lane, Waxhaw, NC 28173

Ph: (704) 225-3082

Fax: (704) 225-3092

Toll Free: (866) 592-9858

Manufacturers of:

RIGID-ROCK & SURE-TOUGHPremium Products